Casting terminology and definitions

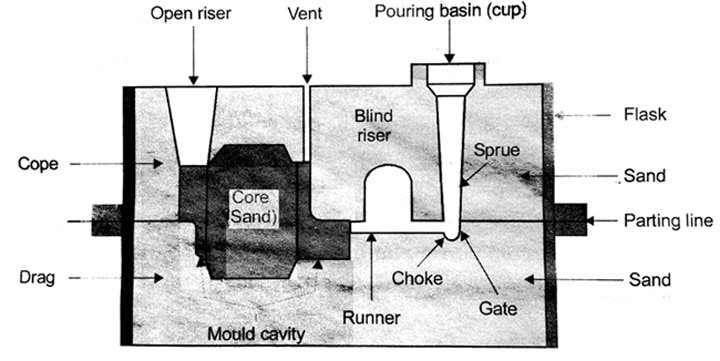

Casting is one of the oldest manufacturing processes in production. In this process, a hollow cavity is designed as per the shape of the final product. Mould is prepared as per the shape of this cavity. Usually, the mould is filled with sand and the outer shell is made of wood. Molten metal is poured into this cavity and allowed to cool. In this way, mass production of any product can be done. Here are different terms of casting terminology.

Here are some common terms used in casting process:

- Pattern: A replica of the part to be cast, used to create a mould.

- Mould: A cavity made from a pattern that is filled with molten metal to form the cast component.

- Core: A removable insert placed inside the mould to create internal features in the cast component.

- Gating System: The channels through which the molten metal is introduced into the mould.

- Riser: A reservoir of molten metal that acts as a source of supply for feeding the casting as it solidifies and shrinks.

- Runners: Channels connecting the gating system to the mould cavity.

- Fillet: A rounded corner or edge at the junction of two surfaces.

- Draft: The angle of taper on the sides of the pattern to allow easy removal from the mould.

- Vent: A small opening in the mould to allow air and gases to escape during casting.

- Shakeout: The process of removing the cast component from the mould after solidification.

- Fettling: The process of removing any rough edges, flash, or excess metal from the cast component.

- Heat Treatment: The process of heating and cooling the cast component to alter its mechanical properties.

Casting terminology and definitions

Core

The core is the hollow cavity of the casting

Runner

The passageway through which molten metal flow is regulated before they reach to the cavity is called the runner.

Gate

The actual entry point of the molten metal

Chills

Metallic objects placed in the mould to increase cooling rate. Chills are made from the material with high thermal conductivity.

Chapltes

They are metallic spacing used to support cores inside the cavity.

Riser

It is a reservoir of additional molten metal to compensate the reduction in volume due to shrinkage after solidification starts.

Also read: Cutting tool terminology

These are some basic casting terminology.

I know this if off topic but I’m looking into starting my own weblog and was curious what all is required to get set up? I’m assuming having a blog like yours would cost a pretty penny? I’m not very internet savvy so I’m not 100 certain. Any recommendations or advice would be greatly appreciated. Cheers