Gear terminology with defination

Gears are widely used in many applications and industries in machines. The primary function of gear is ti transmit power from one place to another place, To transmit power and get maximum work at the minimum input, gears are designed accordingly. Here are some basic definitions used in gear terminology.

Gear Terminology

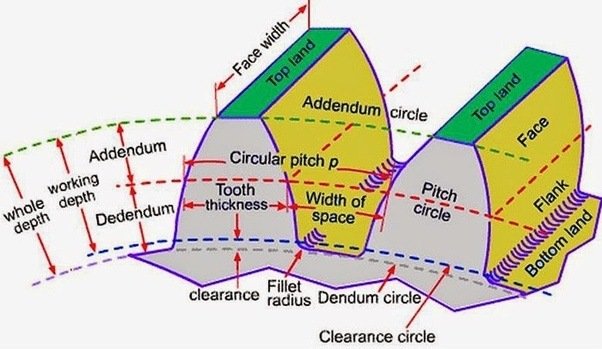

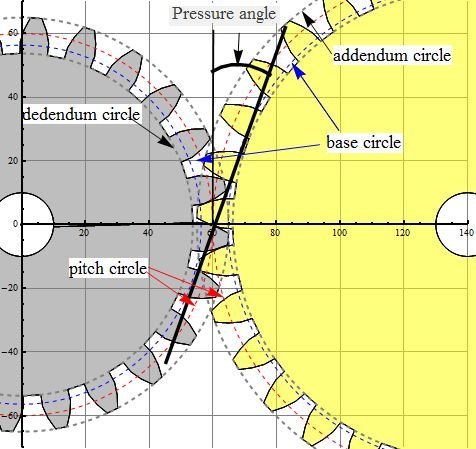

Pitch circle

It is an imaginary circle drawn on gear profile in such a way that a pure rolling motion on this circle gives the motion which is exactly similar to the gear motion.

Pitch point

It is the point where the two pitch circle of the mating gears touch each other.

Pressure angle

It is the angle between common normal at the point of contact at a pitch point. In gear terminology, pressure angle plays a crucial part in gear design.

The standard value of pressure angles are 14 1/2, 20 and 25

Module

The module is defined as the ration of pitch circle diameter in mm to the number of teeth.

m = D/T where D is dia in mm and T is number of teeth

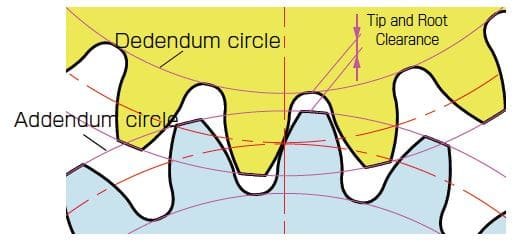

Addendum circle

A circle drawn from the top of the top of the tooth and concentric to pitch circle is known as addendum circle.

The addendum is the radial distance between pitch circle and addendum circle which is equal to 1 module.

Dedendum circle

A circle drawn from the bottom of the teeth and concentric with pitch circle is known as dedendum circle.

The dedendum is the radial distance between pitch circle and dedendum circle.

Circular pitch

It is a distance along a pitch circle from one point on a tooth to the corresponding point on the next tooth

C = ( Pi*D ) / T

where D is pitch circle diameter

T is number of teeth

C = space width + tooth thickness

Diametral pitch

It is the ratio of the number of teeth to the pitch circle diameter. (Diameter need to be in mm)

Circular pitch * Diametral pitch = Pi

Tooth thickness

It is the thickness of the tooth measured along the pitch circle

Tooth space

The space between the consecutive teeth measured along the pitch circle.

Backlash

Difference between tooth space and tooth thickness is known as backlash. Backlash is provided to prevent jamming of gears due to thermal expansion.

Face

The portion of the tooth profile above the pitch surface is known as the face.

Flank

The portion of the tooth profile below the pitch surface is known as flank.

Profile

The curvature contained by face and flank is known as the profile.

Path of contact

It is the path traveled by the point of contact from the starting of engagement to the end of the engagement.

POC = path of approach + path of recess

Arc of contact (AOC)

It is the path traced by a point on the pitch circle during starting of engagement to the end of the engagement

Gear ration (G)

G= T/t

where T number of teeth on gear and t is number of teeth on pinion (small gear)

Velocity ration (VR)

VR = 1/ GR

Angle of action

Angle turned by gear from the beginning of the engagement to the end of engagement of a pair of teeth.

The angle of action = angle of approach + angle of recess

Contact ration (CR)

Contact ration represents the number of pair of teeth in contact.

CR= AOC/circular pitch = Angle of action/Pitch angle

Also read: Types of mechanism

These are some basic terms related to gear terminology.