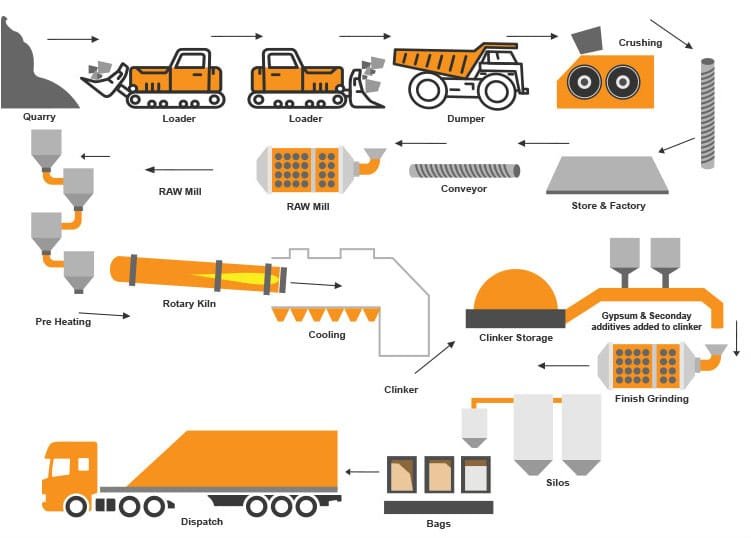

Cement production process in factory

Cement is widely used in construction industry due to its property of bonding with concrete and strength. Any manufacturing process includes series of operations.

Cement production process primarily includes 3 stages.

- Raw material mining/extraction and transportation

- Material processing

- Proportioning, blending and grinding

- Preheating

- Kiln

- Cooling and final grinding

- Packing and shipping.

Raw materials extraction stage

Limestone is the raw material for cement. Cement is extracted from it. In addition to this, other materials like shale, fly ash, bauxite are also required for production of cement. Raw material is transported to production site via truck or train.

Material processing stage

After collecting raw material at production site, raw material handling is the first stage. Here limestone and clay are mixed in proportion of 80% limestone 20 % clay. Then this mixture is grind under rollers crusher to prepare homogenous mixture.

After grinding material is heated in preheating chamber.

Kiln is the rotating furnace and also known as heart of cement production plant. Here raw material is heated up to 1450 degree. At this temeprature, decarbonisation process takes palce where limestone releases carbon dioxise. Chemical reaction between calcium and silicon dioxide forms cement. (Calcium silicate). Kiln is fueled by coal or natural gas.

After cooling material coming out of kiln using forced air from cooling air fan. , final grinding is carried out. during final grinding, gypsum is added which controls setting of cement.

Packing ans shipping

After final grinding, packing of cement is carried out. This is final stage of cement production process where packed cement is stored in warehouses and shipped by trucks or train.